Product Name: Cobalt Carbide (Co3C)

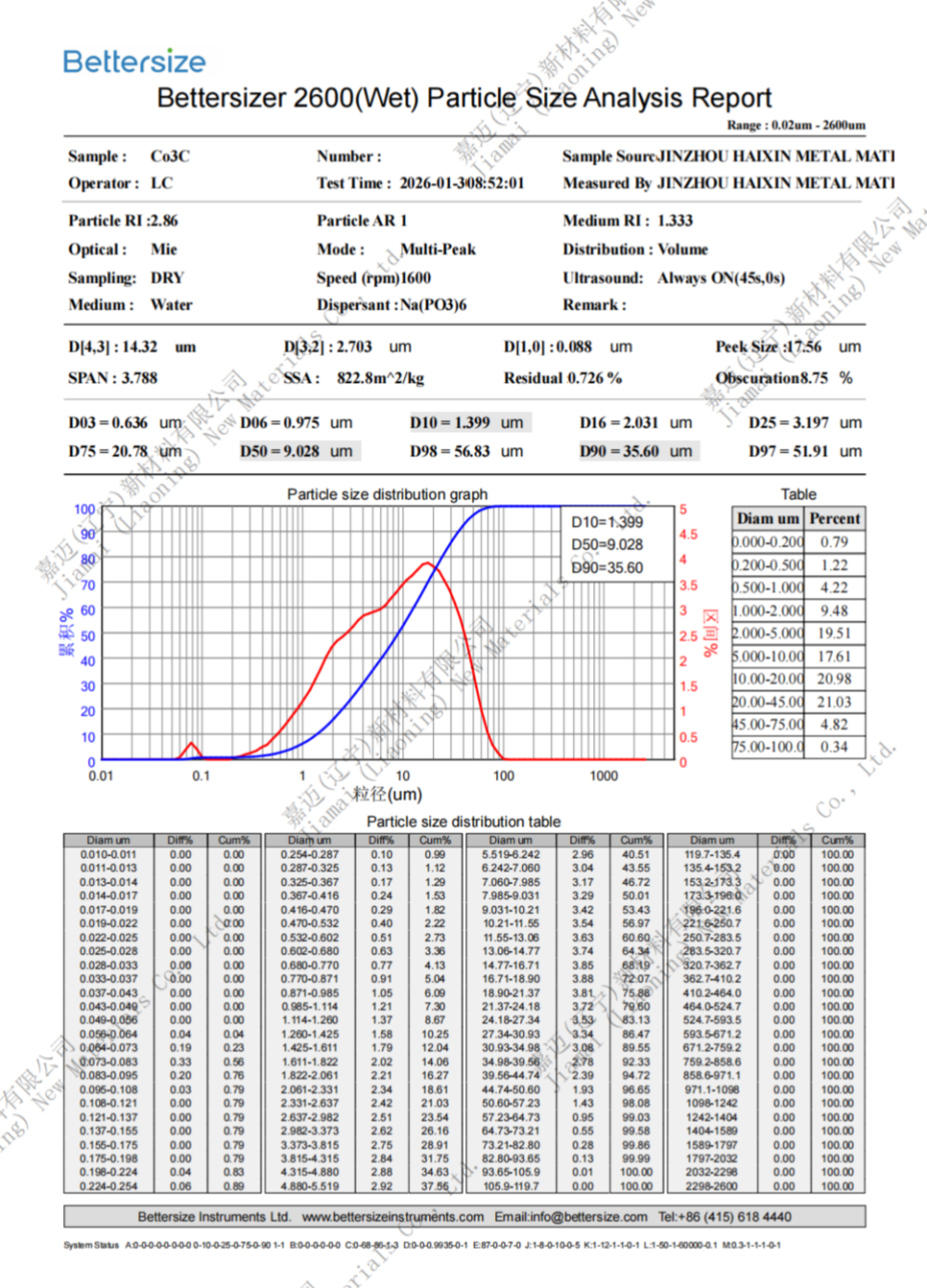

Specification: 0.8-10um (D50)

Appearance: Irregular

Color: Black Grey

Properties: High hardness, high melting point, high conductivity, high catalytic activity, wear resistance, and excellent catalytic performance

Application: It can be used to prepare wear-resistant coatings or composite materials, and is also an important functional catalytic material

Cobalt Carbide

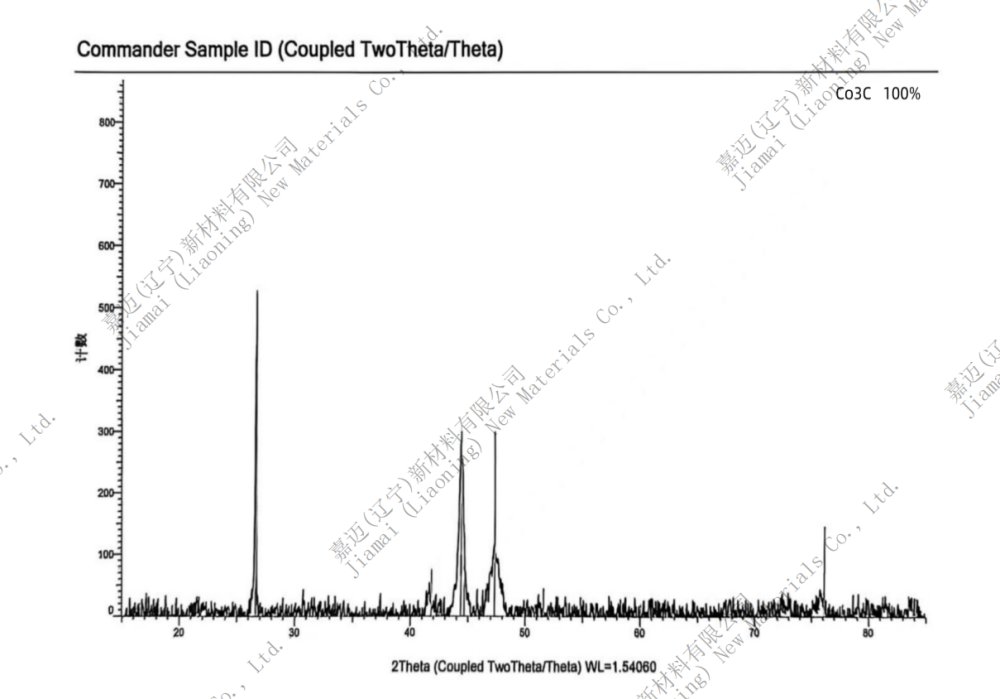

Chemical formula: Co3C

Melting point: 1400 ° C

Density: 4.13 g/cm ³

Appearance: Grey black powder

Crystal System: Hexagonal

Preparation method

1. Direct carbonization of cobalt metal or cobalt oxide: High temperature treatment of cobalt metal or cobalt oxide in a controlled carbon source (such as CO, CH.) atmosphere.

2Co+CH ₄ → Co ₂ C+2H ₂ or 2Co+CO → Co ₂ C+CO ₂

2. Chemical vapor deposition: using cobalt organic metal precursors for decomposition deposition.

3. Solution method: Synthesize nano-sized cobalt carbide through organometallic chemical methods at lower temperatures.

purpose

1. Catalytic field: High efficiency catalysts for Fischer Tropsch synthesis, hydrogenation desulfurization, and organic catalytic reactions, with activity superior to some cobalt based carbides.

2. Hard coating: wear-resistant coating on the surface of precision cutting tools and micro molds, combined with other coating materials to enhance wear resistance and impact resistance.

3. Energy materials: Negative electrode additives for lithium-ion batteries to improve electrode conductivity and charge discharge efficiency, requiring modification to enhance cycling stability.

Packaging and Storage

Vacuum/high-purity inert gas sealed packaging, stored in a dry, cool, and dark place; Stay away from high temperatures, oxidants, and humid environments. Long term exposure to air is strictly prohibited to prevent oxidation and disproportionation deterioration