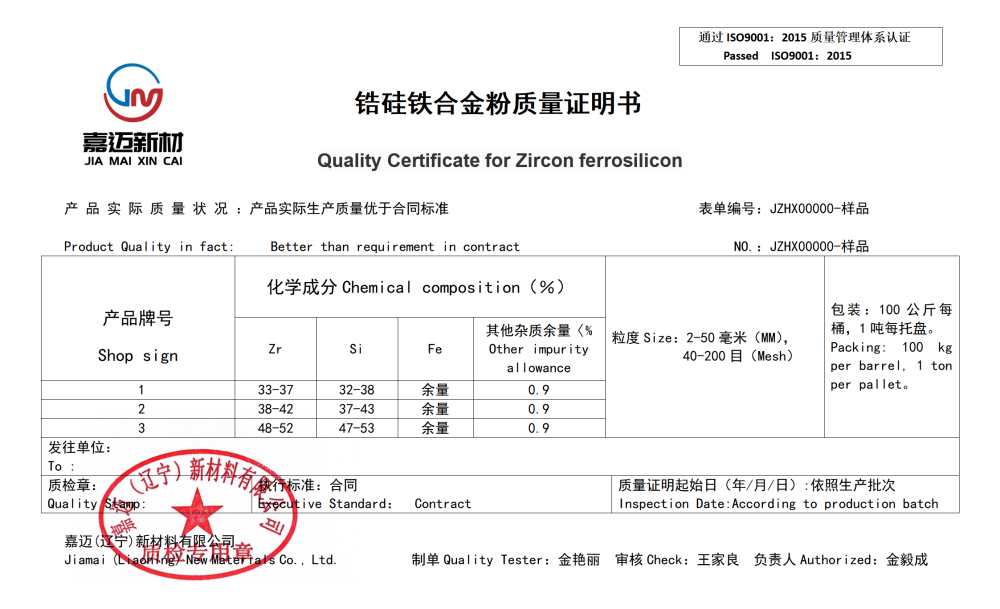

Product Name: Zirconium Silicon Iron (ZrSiFe)

Specifications: 100 mesh, 200 mesh, 325 mesh

Appearance: Irregular

Color: Black Grey

Features: Good corrosion resistance, high temperature stability and mechanical properties, excellent magnetic properties

Application: Steel making, welding rods, aerospace, electronic and electrical, chemical and other fields

Ferrozirconium silicon is one of the strongest deoxidizers in steelmaking and the special role of zirconium in steel, ferrozirconium silicon as a deoxidizer

and Alloy additives for special applications in superalloys, low-alloy high-strength steel, ultra-high strength steel and cast iron,It is then used in atomic

technology, aerospace manufacturing, radio technology and so on. Ferrozircon has a density of about 3.5g/cm3 and a melting temperature .The temperature

range is 1260~1345℃.

The main function of ferrozirconium silicon as a inoculant is to increase density, reduce melting point, strengthen absorption, etc.The zirconium element

in zircon silicon iron has a strong deoxidation effect, so zirconium also has deoxidation, desulfurization, nitrogen fixation, and improve liquid iron.Fluidity, reduce

the ability to form pores.

Ferrozirconium silicon inoculant has strong anti-decay ability and promotes the formation of A-type graphite. If combined with A certain amount of Ba and

Ti elements,The inoculation effect of ferrozirconium silicon inoculant is very good, which can not only promote the A-type graphite, increase the nucleation ability

and increase the eutectic clusters.The number reduces segregation, and can improve the uniformity of the tissue.