Product Name: Nickel Monosilicide (Ni2Si)

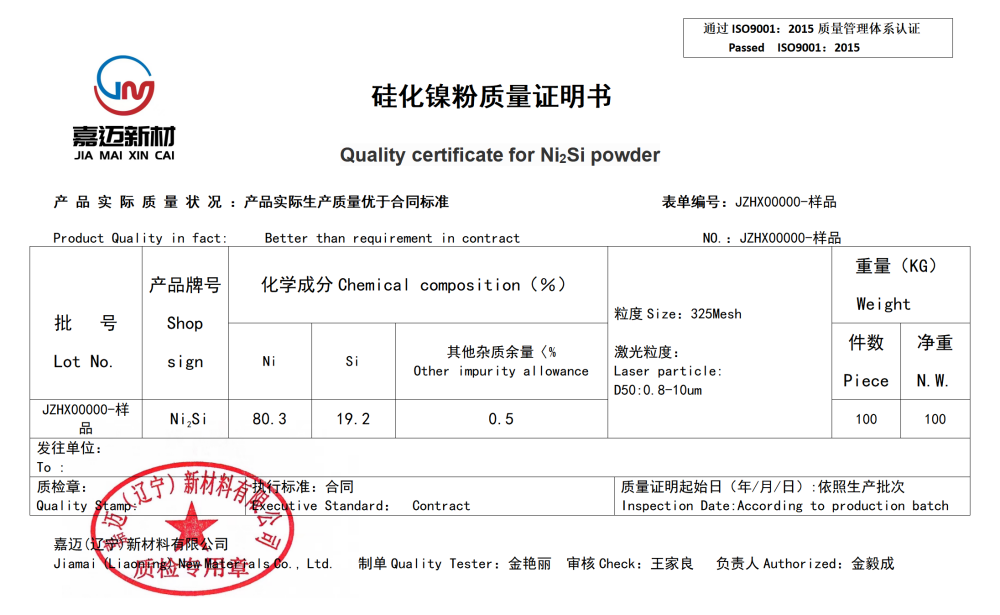

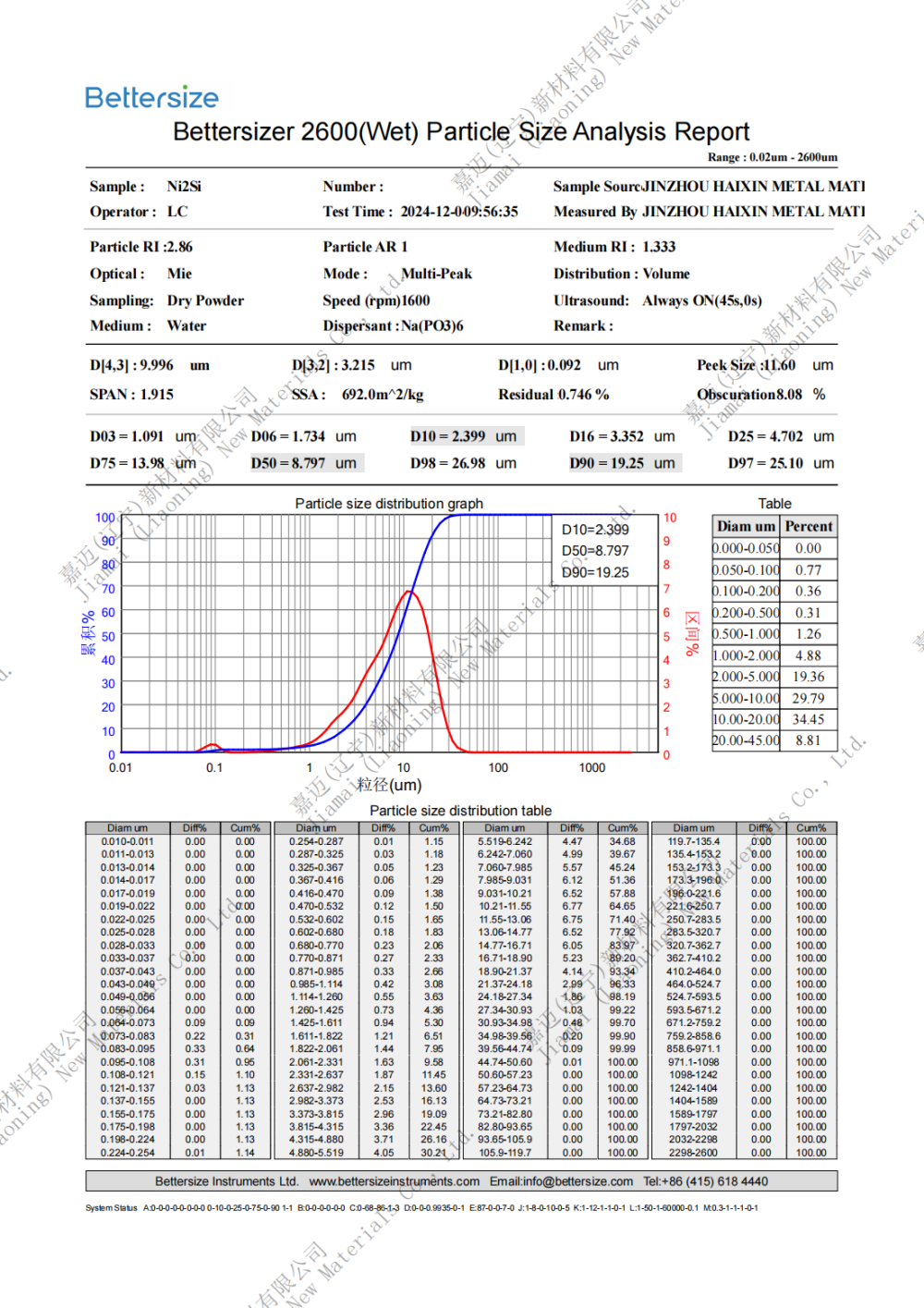

Specification: 0.8-10um (D50)

Appearance: Irregular

Color: Black Grey

Features: high melting point, good chemical stability

Usage: In fields such as batteries, catalysts, optoelectronic devices, and materials science

dinickel silicide

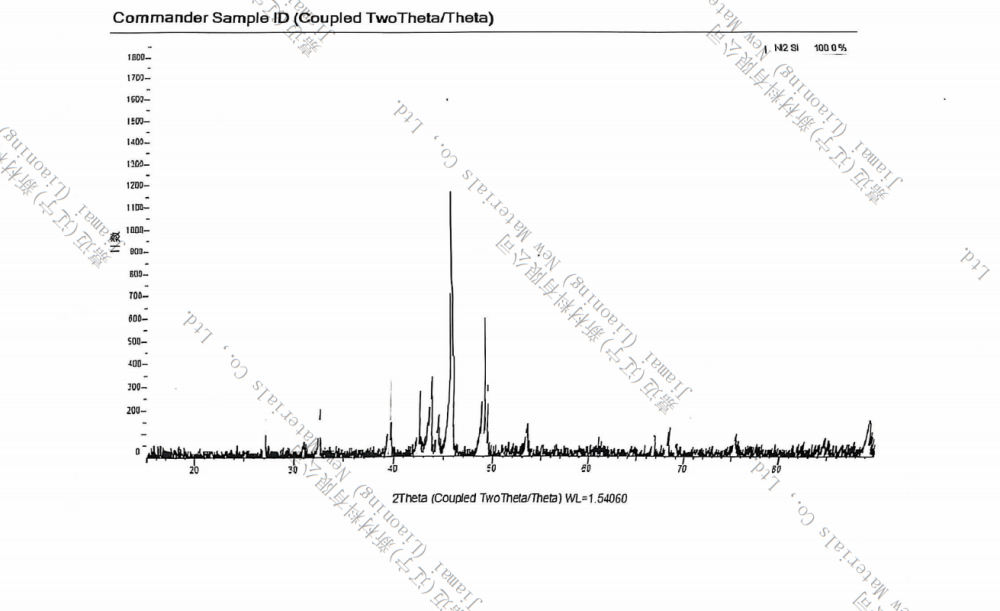

Chemical formula: Ni2Si

Molecular weight: 145.472

CAS login number: 12059-14-2

EINECS login number: 235-033-1

Melting point: 1255 ℃

Density: 7.4 g/cm ³

MDL Number: MFCD00151367

Method: Silicon oxide, nickel (II) oxide, and aluminum can be obtained by heating them in a blast furnace.

Properties: Nickel silicide rapidly dissolves in hydrofluoric acid, slowly dissolves in hydrochloric acid, and is insoluble in water. Nickel silicide reacts fiercely with fluorine at room temperature, reaching white heat, and reacts with chlorine gas at red heat. Nickel silicide decomposes upon contact with aqua regia.

Nickel silicide (Ni ₂ Si) is an important transition metal silicide with high hardness, high melting point, good electrical conductivity, and thermal stability. Its application areas mainly include:

1. Electronic materials

Electronic packaging material: Nickel silicide has good conductivity and thermal expansion coefficient matching, which can effectively protect packaged electronic devices.

2. Electrode material: Used for manufacturing electrodes in electronic devices such as capacitors and integrated circuits. Its high melting point and heat resistance enable it to maintain stable conductivity even in high temperature environments.

3. Mechanical processing

Cutting tool coating: As a coating material for cutting tools, it improves the hardness and wear resistance of the tool, and extends its service life.

Bearing coating: a wear-resistant and corrosion-resistant coating used for bearings to reduce friction losses.

4. Energy sector

Catalyst carrier: As a catalyst carrier for energy conversion devices such as fuel cells and electrolyzed water equipment, it enhances reaction activity and stability.

5. Other applications

High temperature ceramic materials: used for the preparation of aerospace devices and high-temperature tools.

Coating additives: increase the hardness and wear resistance of coatings.

Packaging and storage: This product is packaged in an inert gas filled plastic bag, sealed and stored in a dry and cool environment. It should not be exposed to air to prevent moisture from causing oxidation and aggregation, which may affect dispersion performance and usage effectiveness; The packaging quantity can be provided in separate packages according to customer requirements.