Product Name: Iron Disilicide (FeSi2)

Product Name: Iron Disilicide (FeSi2)

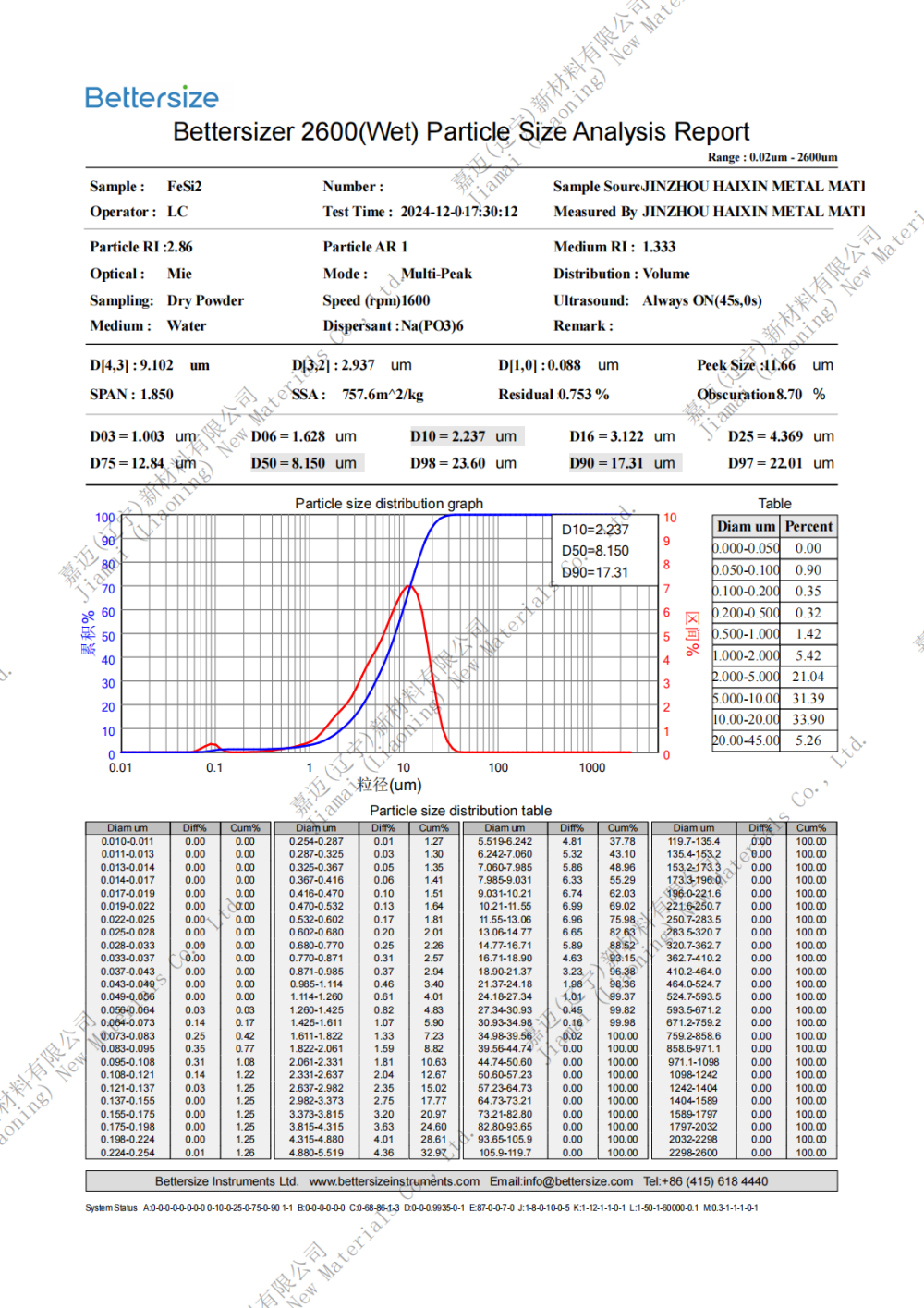

Specification: 0.8-10um (D50)

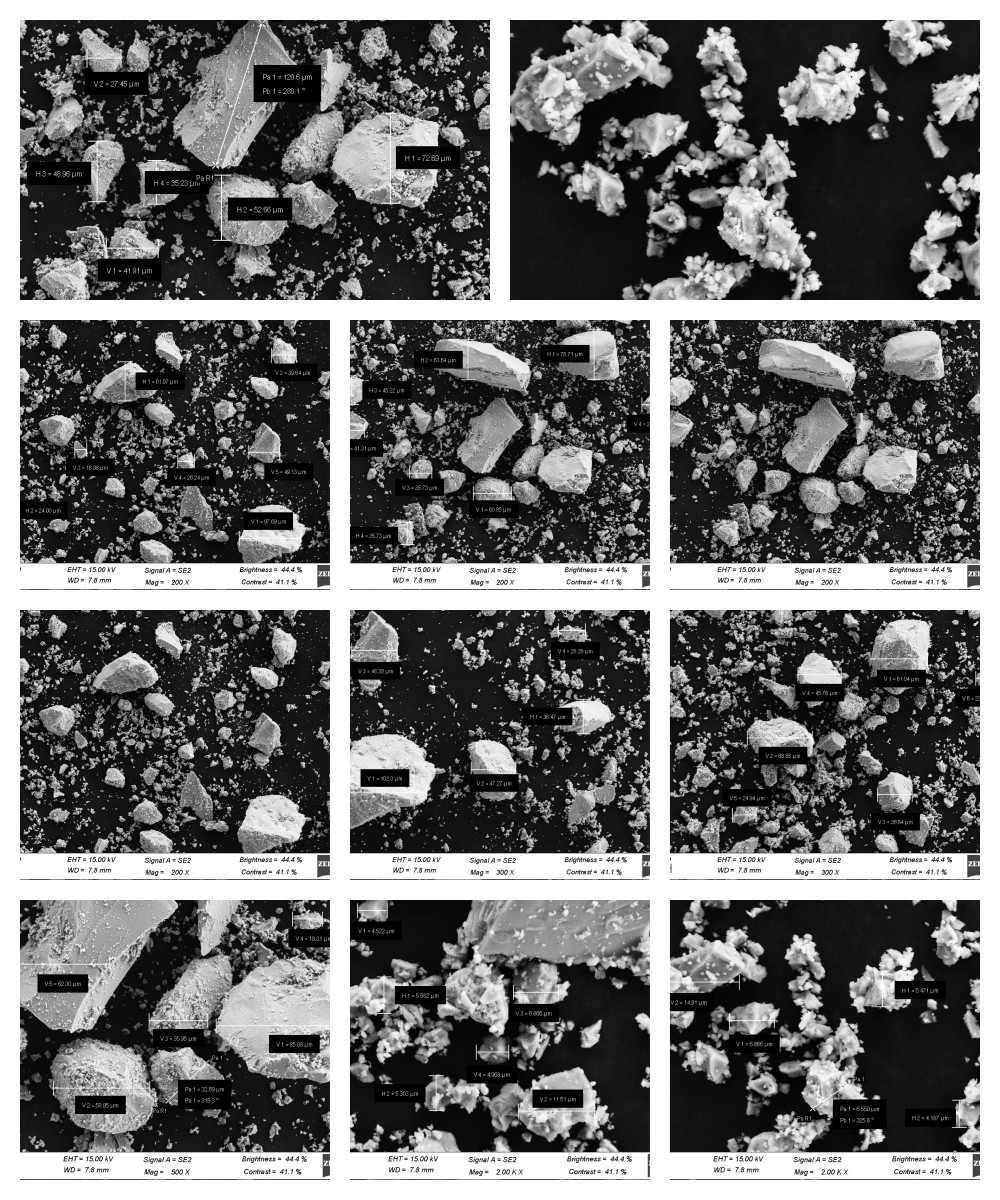

Appearance: Irregular

Color: Black Grey

Characteristics: Stable under normal temperature and pressure

Application: In the fields of chemical engineering, electronics, and materials, et

Iron Silicide

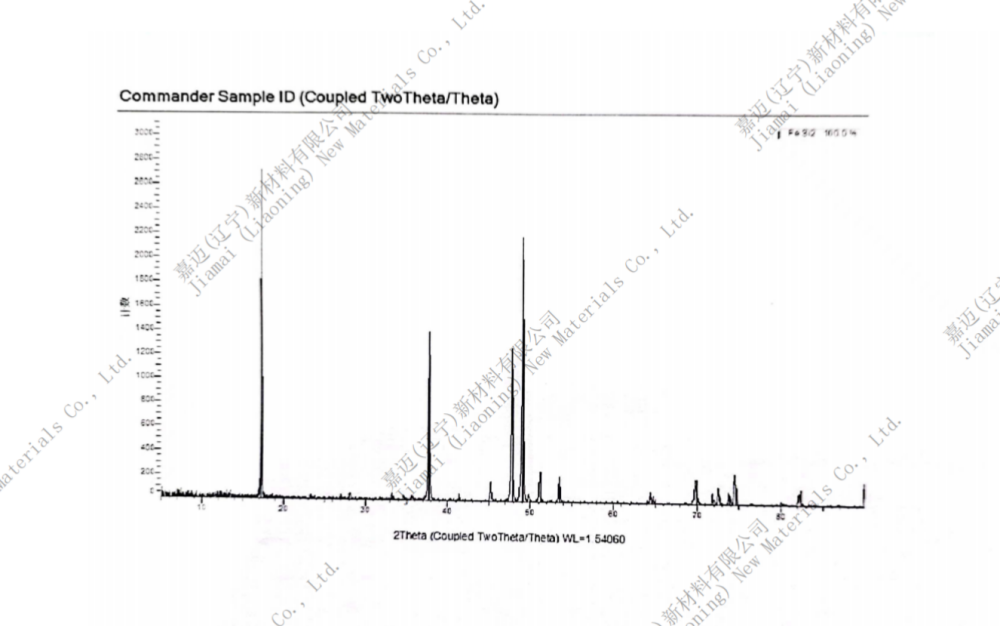

Chemical formula: FeSi₂

English: IRON SILICIDE

Molecular weight: 119.975

CAS: 12022-99-0

Melting point: 1410 ℃

Density: 4.79 g/cm ³

EINECS number: 912-631-7

Performance: Insoluble in water, nitric acid, and hydrochloric acid, soluble in hydrofluoric acid and alkaline solution

Appearance: Grey powder

Production process:

Mix iron powder and silicon powder in a molar ratio of 1:2, and co crystallize or sinter them in a vacuum or inert atmosphere.

Property: Iron silicide is an inorganic substance with the chemical formula FeSi ₂, gray powder, odorless, tetragonal crystal, insoluble in water.

Application areas:

1. Used as a deoxidizer and alloying agent in the steelmaking industry. In order to obtain steel with qualified chemical composition and ensure its quality, deoxidation must be carried out in the final stage of steelmaking. The chemical affinity between silicon and oxygen is high, so ferrosilicon is a strong deoxidizer for precipitation and diffusion deoxidation in steelmaking. Ferrosilicon not only meets the deoxidation requirements of steelmaking, but also has desulfurization performance and advantages such as high specific gravity and strong penetration. In addition, in the steelmaking industry, silicon iron powder is often used as a heating agent for steel ingot caps to improve the quality and recovery rate of steel ingots due to its ability to release a large amount of heat at high temperatures.

2. Electronics and Semiconductor Industry

Thermoelectric materials: have high thermoelectric conversion efficiency, can convert waste heat into electrical energy, and are used in industrial waste heat recovery systems, spacecraft radioactive isotope thermoelectric generators (RTGs), etc.

Semiconductor devices: As narrow bandgap semiconductors, they are used to manufacture high-temperature sensors, infrared detectors, and magnetoresistance devices.

3. Magnetic materials

Featuring ferromagnetism and high resistivity, used for: magnetic heads (hard disk drive read/write heads)

Magnetic shielding material (reducing electromagnetic interference): Soft magnetic material in high-frequency transformers and inductors

4. Photovoltaics and New Energy

β - FeSi ₂ solar cells are considered as candidate materials for environmentally friendly thin-film solar cells due to their strong light absorption ability, high stability, and absence of rare elements (still in the research stage).

5. Hydrogen energy field

Iron silicide can be used as a catalyst carrier for hydrogen production through water splitting reactions.

6. High temperature and protective coating

FeSi ₂ and other silicified iron exhibit excellent oxidation resistance at high temperatures and are used as protective coatings for aircraft engine blades and gas turbine components.

Corrosion resistant coatings, such as siliconized iron coatings, can extend the lifespan of metal substrates in chemical equipment or marine environments.

Packaging and storage: This product is packaged in an inert gas filled plastic bag, sealed and stored in a dry and cool environment. It should not be exposed to air to prevent moisture from causing oxidation and aggregation, which may affect dispersion performance and usage effectiveness; The packaging quantity can be provided in separate packages according to customer requirements.